Wood Plastic Exterior Wall Cladding interlocking

Type:

WPC wall panel

Warranty: More than 5 years

Project Solution Capability:graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

Application:Interior/ Exterior

Design Style:Modern

Place of Origin:Anhui, China

Brand Name:Sentai

Color: customized

Length:2.2m, 2.9m, 3.6m or customized

Advantage: waterproof+anti-scratch anti-stain

Certification:FSC INTERTEK TUV

Package:Pallet Packaging

Feature:Waterproof+ECO-Friendly

Composition:60% Wood/bamboo Powder, 30% Plastic, 10% Additives

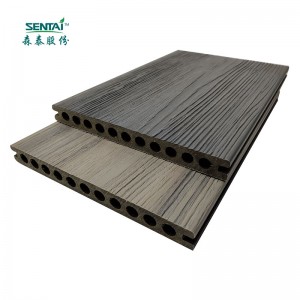

Surface:grooves, 3D embossing, wood look, ladder shaped, hollow

MOQ:200 Square Meters

WPC Wall Cladding

WPC Composite outdoor wall cladding is made of 30% HDPE (Grade A recycled HDPE), 60% Wood or Bamboo powder(Professionally treated dry bamboo or wood fiber), 10% Chemical Additives (Anti-UV agent, Antioxidant, Stabilizes, Colorants, Lubricant etc.)

WPC composite wall panel not only has real wood texture, but also has longer service life than real wood and requires little maintenance. So, WPC composite wall cladding is a good alternative of other wall decoration.

WPC (abbreviation: wood plastic composite)

Advantages of WPC (Wood Plastic Composite)

1. Looks and feels like natural wood but less timber problems;

2. 100% recycle, eco-friendly, saving forest resources;

3. Moisture/Water resistant, less rotten, proven under salt water condition;

4. Barefoot friendly, anti-slip, less cracking, less warping;

5. Requires no painting, no glue, low maintenance;

6. Weather resistant, suitable from minus 40 to 60°c;

7. Easy to install and clean, low labor cost.

WPC Outdoor Wall Cladding Used For?

Because Sentai WPC outdoor wall cladding has following good performance: high pressure resistance, weather resistance, scratch resistance, waterproof, and fireproof, WPC composite cladding has long service life compared to other cladding. That is why wpc composite cladding is wisely used at outdoor environment, such as gardens, patio, parks, seaside, residential housing, gazebo, balcony, and so on.

FAQ

What’s your MOQ?

What’s the best price for your products?

What’s the delivery time?

What’s your payment terms?

What’s your packing?

How can I get the samples?

Wood plastic composites, abbreviated as WPC, is a new type of composite material booming at home and abroad, which refers to the use of polyethylene, polypropylene and polyvinyl chloride as the base material or carrier, adding wood flour, rice husk, straw and other plant fibers to mix into new modified materials. The composite particles are prepared by mixing and granulation. Then through extrusion, molding, injection molding and other plastic processing processes, the plate or profile is produced.

WPC material has good elastic modulus because it contains plastic. In addition, because it contains fibers and is fully mixed with plastics, it has the same physical and mechanical properties as hardwood, such as compression resistance and bending resistance, and its durability is significantly better than ordinary wood materials. The surface hardness is high, generally 2-5 times that of wood.

It is mainly used in building materials, furniture, logistics and packaging industries. Plastic and wood powder are mixed in a certain proportion and granulated, and then hot extruded into a plate, which is called extruded wood plastic composite plate.